Inspection and maintenance

Inspection of chain

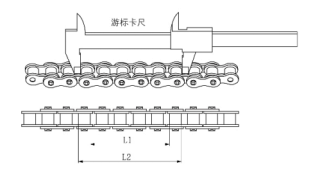

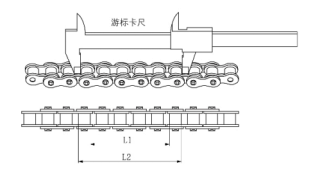

■ Simple method for determination of chain elongation

Straighten both ends of the chain and measure as shown in the picture on the right.

Measurement length L= (L1+L2) / 2

Standard length Ls = standard pitch X number of measured pitches

Elongation Le = (L-LS)/Ls x 100%

■ The limit of chain elongation

If the chain elongation is too large, the chain will not be able to drive smoothly and reduce the transmission efficiency. Therefore, when the elongation exceeds a certain limit, a new chain must be replaced, as shown in the table below.

■ Check the appearance of the chain

1) whether the inner/outer chain piece is deformed, cracked and corroded.

2) The pin shaft is not deformed or rotated, rust.

3) whether the roller cracks, damage, excessive wear.

4) Whether the joint is loose and deformed.

5) When running, there is no abnormal sound or abnormal vibration, whether the lubrication condition of the chain is good.

Chain maintenance

■ Correct disassembly: before installation, pay attention to make the two sprocket axis parallel, and the two sprocket rotation plane should be located in the same plumb plane, otherwise it will cause off the chain or abnormal wear.

When installing the chain, wrap the chain around the sprocket before threading it into the chain pin. The chain pin should be pierced from inside out so that the connecting plate can be installed and locked from the outside. When disassembling, after removing the locking piece, the two connecting pins on the same connecting plate can be gently knocked by rotation with a hammer, the pin shaft can be pulled out, and the chain can be unloaded. If the chain pin has been rivet head thickened, can be removed after grinding.

■ Sprocket mounted on the shaft should be free of skew and swing. The end face of two sprockets in the same transmission component should be located in the same plane, sprocket center distance is below 0.5 meters, allowing a deviation of 1 mm; Sprocket center distance above 0.5 m, allow a deviation of 2 mm. But do not allow friction sprocket tooth side phenomenon, if the two wheel offset is too large easy to produce off the chain and accelerated wear. Care must be taken to check and adjust the offset when replacing the sprocket.

■ Chain tightness should be appropriate, too tight increase power consumption, bearing easy to wear; Too loose chain is easy to jump and loose chain. The tightness of the chain is: from the middle of the chain to lift or press down, the center distance between the two sprockets is about 2%-3%.

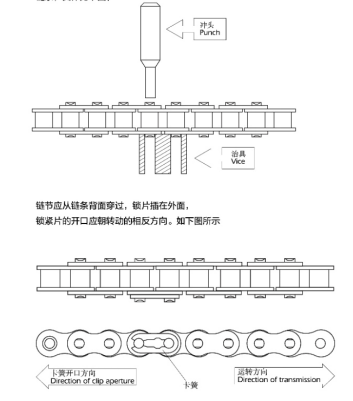

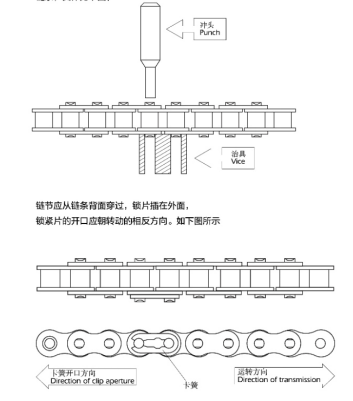

■ Chain elongation after long use, in the case of difficult adjustment, can be removed according to the situation, but must be an even number. To be specific, the riveting part of the pin shaft that is to be truncated and connected can be grinded off with a grinding wheel, and the pin shaft can be knocked off with a punch to remove the chain, as shown in the figure below:

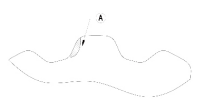

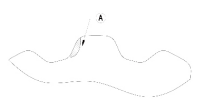

■ After sprocket wear is serious, replace the new sprocket and the new chain at the same time to ensure good engagement. Can not only replace the new chain or new sprocket alone, otherwise it will cause bad meshing to accelerate the wear of the new chain or new sprocket. The figure on the right shows the shape of a worn sprocket tooth. This will cause the chain attached to the sprocket can not run smoothly, at this time can be used by grinding off the A section or turning over (refers to the sprocket used in the adjustable surface). The amount of wear at the joints is determined by the size and speed of the chain. When the amount of wear affects the normal operation of the chain drive, corrective measures should be taken or the relevant parts should be replaced.

■ The old chain can not be mixed with part of the new chain, otherwise it is easy to produce impact in the transmission, break the chain.

■ The chain should be lubricated in time during work. Lubricating oil must enter the fit gap between roller and sleeve to improve working conditions and reduce wear.

■ When the machine is stored for a long time, the chain should be removed and cleaned with kerosene or diesel oil, and then stored in a dry place with oil or butter to prevent corrosion.

Lubrication of chain

The lubrication of the chain drive depends on the application situation, temperature, chain line speed, etc.

■ Impact of application situation

Open transmission, such as all kinds of combine harvester, windrower and other chains should use grease lubrication.

Closed drive, such as walking tractor chain drive box, should be lubricated with oil.

■ Temperature impact

It is generally recommended to use lubrication in the range of -5℃~ +60℃.

Oil with small viscosity is used in winter, and oil with large viscosity is used in summer.

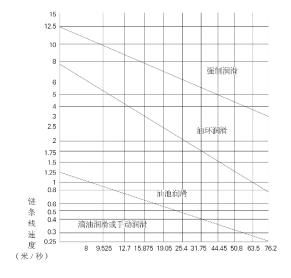

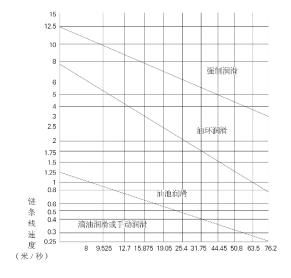

■ Effect of linear velocity

Lubrication mode is directly related to the chain linear speed,

Specific can refer to the right of the selected lubrication mode.

How the chain is connected

■ The type and length of the chain, the number of chain links and the connection of the relationship.

■ Supply mode of chain and connection -- In order to clarify the connection mode of supply chain and connecting parts, this paper gives several conventional combination mode, and users can also propose special connection supply mode.

Chain use faults and solutions

■ Simple method for determination of chain elongation

Straighten both ends of the chain and measure as shown in the picture on the right.

Measurement length L= (L1+L2) / 2

Standard length Ls = standard pitch X number of measured pitches

Elongation Le = (L-LS)/Ls x 100%

■ The limit of chain elongation

If the chain elongation is too large, the chain will not be able to drive smoothly and reduce the transmission efficiency. Therefore, when the elongation exceeds a certain limit, a new chain must be replaced, as shown in the table below.

| Sprocket teeth | elongation(%) |

| Under 40 teeth | 2.0 |

| 40 ~ 60 teeth | 1.5 |

| 60 ~ 80 teeth | 1.2 |

| From 80 to 100 | 1.0 |

| More than 100 teeth | 0.8 |

1) whether the inner/outer chain piece is deformed, cracked and corroded.

2) The pin shaft is not deformed or rotated, rust.

3) whether the roller cracks, damage, excessive wear.

4) Whether the joint is loose and deformed.

5) When running, there is no abnormal sound or abnormal vibration, whether the lubrication condition of the chain is good.

Chain maintenance

■ Correct disassembly: before installation, pay attention to make the two sprocket axis parallel, and the two sprocket rotation plane should be located in the same plumb plane, otherwise it will cause off the chain or abnormal wear.

When installing the chain, wrap the chain around the sprocket before threading it into the chain pin. The chain pin should be pierced from inside out so that the connecting plate can be installed and locked from the outside. When disassembling, after removing the locking piece, the two connecting pins on the same connecting plate can be gently knocked by rotation with a hammer, the pin shaft can be pulled out, and the chain can be unloaded. If the chain pin has been rivet head thickened, can be removed after grinding.

■ Sprocket mounted on the shaft should be free of skew and swing. The end face of two sprockets in the same transmission component should be located in the same plane, sprocket center distance is below 0.5 meters, allowing a deviation of 1 mm; Sprocket center distance above 0.5 m, allow a deviation of 2 mm. But do not allow friction sprocket tooth side phenomenon, if the two wheel offset is too large easy to produce off the chain and accelerated wear. Care must be taken to check and adjust the offset when replacing the sprocket.

■ Chain tightness should be appropriate, too tight increase power consumption, bearing easy to wear; Too loose chain is easy to jump and loose chain. The tightness of the chain is: from the middle of the chain to lift or press down, the center distance between the two sprockets is about 2%-3%.

■ Chain elongation after long use, in the case of difficult adjustment, can be removed according to the situation, but must be an even number. To be specific, the riveting part of the pin shaft that is to be truncated and connected can be grinded off with a grinding wheel, and the pin shaft can be knocked off with a punch to remove the chain, as shown in the figure below:

■ After sprocket wear is serious, replace the new sprocket and the new chain at the same time to ensure good engagement. Can not only replace the new chain or new sprocket alone, otherwise it will cause bad meshing to accelerate the wear of the new chain or new sprocket. The figure on the right shows the shape of a worn sprocket tooth. This will cause the chain attached to the sprocket can not run smoothly, at this time can be used by grinding off the A section or turning over (refers to the sprocket used in the adjustable surface). The amount of wear at the joints is determined by the size and speed of the chain. When the amount of wear affects the normal operation of the chain drive, corrective measures should be taken or the relevant parts should be replaced.

■ The old chain can not be mixed with part of the new chain, otherwise it is easy to produce impact in the transmission, break the chain.

■ The chain should be lubricated in time during work. Lubricating oil must enter the fit gap between roller and sleeve to improve working conditions and reduce wear.

■ When the machine is stored for a long time, the chain should be removed and cleaned with kerosene or diesel oil, and then stored in a dry place with oil or butter to prevent corrosion.

Lubrication of chain

The lubrication of the chain drive depends on the application situation, temperature, chain line speed, etc.

■ Impact of application situation

Open transmission, such as all kinds of combine harvester, windrower and other chains should use grease lubrication.

Closed drive, such as walking tractor chain drive box, should be lubricated with oil.

■ Temperature impact

It is generally recommended to use lubrication in the range of -5℃~ +60℃.

Oil with small viscosity is used in winter, and oil with large viscosity is used in summer.

■ Effect of linear velocity

Lubrication mode is directly related to the chain linear speed,

Specific can refer to the right of the selected lubrication mode.

How the chain is connected

■ The type and length of the chain, the number of chain links and the connection of the relationship.

| 链条型号 | 每卷长度(英尺) | 链节数 | 配给连接件数 |

| 25 | 500 | 24000 | 50 |

| 35、06B | 100 | 3200 | 20 |

| 40、08B | 100 | 1800 | 20 |

| 50、10B | 100 | 1920 | 20 |

| 60、12B | 100 | 1600 | 20 |

| 80、16B | 50 | 600 | 10 |

Chain use faults and solutions

| Problems or faults | The reasons causing | Corrective solution method |

| Missing parts | Assembly adjusting | Replace the chain |

| Lost after damage | Identify and eliminate major causes of damage and replace the chain | |

| The chain is the rust of | Be affected with damp be affected with damp | Replace the chain to protect it from moisture |

| Water content in lubricating oil | Replace the lubricating oil, take waterproof measures, and replace the chain | |

| Inadequate lubrication | Redesign the lubrication system and replace the chain | |

| In a corrosive environment | Replace the chain and take measures to protect the chain from corrosion | |

| The lock stopper is missing or damaged | The lock stopper is improperly installed | The opening of the stopper moves in the back direction |

| Run into obstacles | Remove the interference fault and reinstall the lock stopper | |

| Vibration is too large | Replace the sprocket, reduce vibration, and reinstall the stopper | |

| Speed is too high | Reduce the speed or redesign the sprocket and replace the chain | |

| High transmission noise | The chain hits a snag | Remove distractions |

| The shield or shaft is loose | Tighten or install the shield or drive shaft. The chain is out of wear range. Replace the chain | |

| The chain too loose | Adjust the tensioner to achieve the purpose of tensioning the chain | |

| Sprocket wheel wear | Replace the sprocket or turn the sprocket (that is, the force is not working face) to use | |

| The chain and sprocket don't match | Recalculate chain sprocket parameters and select replacement | |

| Drive center distance error is large | Recalculate, determine the reasonable center distance and tension | |

| Inadequate lubrication | According to the parameters, re-determine the lubrication system | |

| Excessive chain pitch | Adopt small distance chain transmission | |

| The number of sprocket teeth is too small | If there is space, increase the number of sprocket teeth | |

| Sprockets are not coplanar | Recalibrate sprocket parallelism and axial displacement as required | |

| The chain will not come off the sprocket | The load fluctuates greatly | Reasonable design of tensioning mechanism |

| Sprockets are badly worn | Replace the sprocket | |

| Sprockets are not coplanar | Aligning sprocket and tensioning drive chain | |

| Excessive chain vibration | The swing of the equipment resonates with the chain drive | Adjust the transmission cycle frequency of equipment or chain |

| The chain of vibration | Use a large sprocket to reduce vibration | |

| High transmission speed | Reduce the speed or use a pitch chain | |

| The reasons causing | Corrective solution method | |

| The chain too loose | Chain tension | |

| The chain is badly worn. | Replace the chain | |

| Sprockets are badly worn | Replace the sprocket | |

| To operate too heavy or overloaded | Eliminate overload factors and redesign the selection of large chain and sprocket | |

| Sprocket not coplanar, unidirectional extrusion | Calibration of sprocket parallelism and axial displacement | |

| Insufficient lubrication chain joint overburning | According to the working condition, the reasonable lubrication mode should be adopted again | |

| Corrosion in parts | Replace with corrosion-resistant chains according to service conditions | |

| Overloading deforms parts | Eliminate overload causes or use reinforced chains | |

| There's a foreign object in the hinge | Clean the chain, add a shield or filter cooling oil | |

| Overload or hard too low, so that the chain plate outside expansion without backlash | Eliminate overload factors; Improve the hardness of parts, or control the raw material decarbonization carbon poor | |

| The corrosion environment produces stress, and the ambient temperature is too low to produce cold brittle | Remove distractions | |

| overloaded | Tighten or install the shield or drive shaft. The chain is out of wear range. Replace the chain | |

| The load is greater than the dynamic load bearing capacity of the chain and fatigue fracture | Adjust the tensioner to achieve the purpose of tensioning the chain | |

| Beating resonance | Replace the sprocket or turn the sprocket (that is, the force is not working face) to use | |

| The chain drive is in vibration for a long time | Recalculate chain sprocket parameters and select replacement | |

| Excessive instantaneous inertia force in transmission | Recalculate, determine the reasonable center distance and tension | |

| overload | According to the parameters, re-determine the lubrication system | |

| Insufficient lubrication overload | Adopt small distance chain transmission | |

| overload | If there is space, increase the number of sprocket teeth | |

| Too fast lubrication is not sufficient | Recalibrate sprocket parallelism and axial displacement as required | |

| Speed is fast | Reasonable design of tensioning mechanism | |

| The small sprocket | Replace the sprocket | |

| The chain tooth climb | Aligning sprocket and tensioning drive chain | |

| Excessive transmission power | Adjust the transmission cycle frequency of equipment or chain | |

| The chain rubs against the shield, regulating wheel, or other object | Eliminate obstacles to the chain; Chain plate wear reaches 5%, chain plate surface has changed color, should replace the chain, eliminate interference. |